TLC Fundamentals – How to make a successful TLC plate (part 3)

Cod Fillet,Cod Fish Fillet,Cooking Cod Fillets,Pan Fried Cod Fillet ZHEJIANG EVERNEW SEAFOOD CO.,LTD , https://www.evernewseafood.com1. Deposition Line & Solvent Front

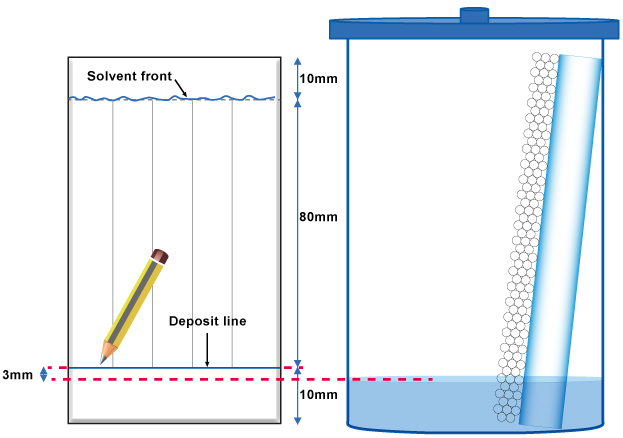

When plotting the deposition line, use a pencil to mark it approximately 3 millimeters above the level of the mobile phase. It's recommended that the migration height be at least 8 centimeters. Make sure the solvent front moves up to about 1 centimeter from the top edge of the thin-layer chromatography (TLC) plate.

2. How to Prepare the Deposition

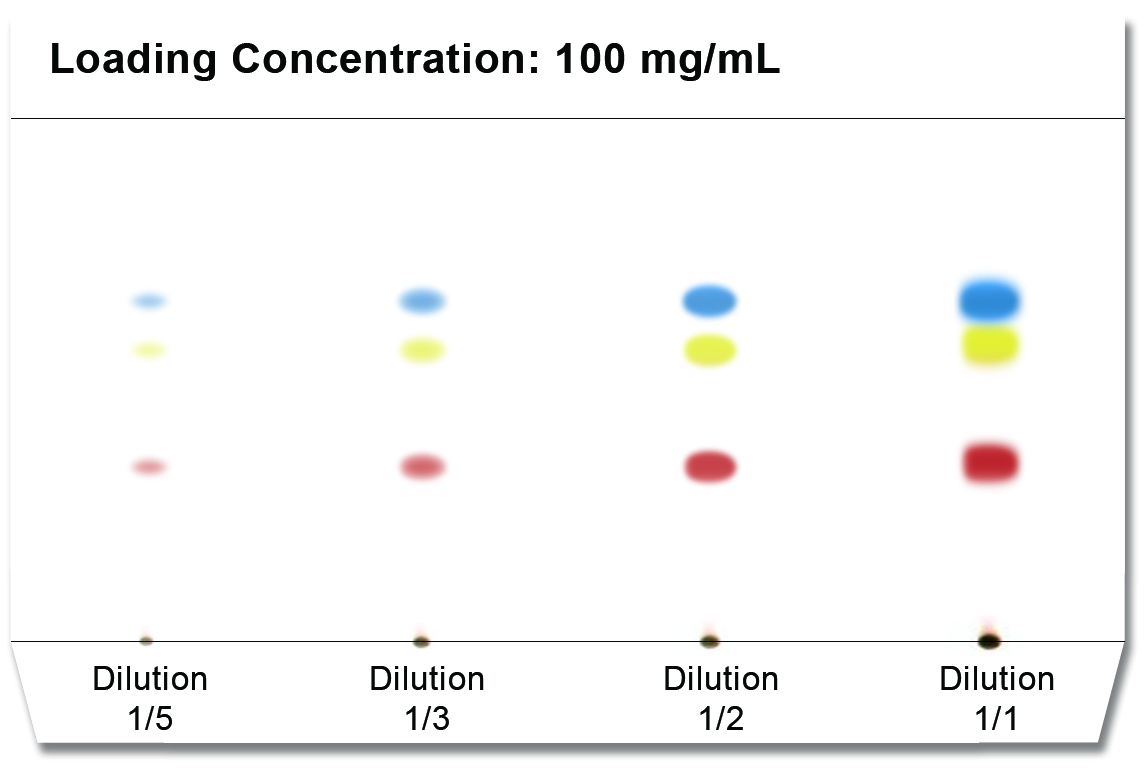

a) Sample Concentration

It’s crucial to prevent overloading during deposition. For best results:

- Standard samples should have a concentration of 0.1 mg/L.

- For test samples, the concentration shouldn’t exceed 2%.

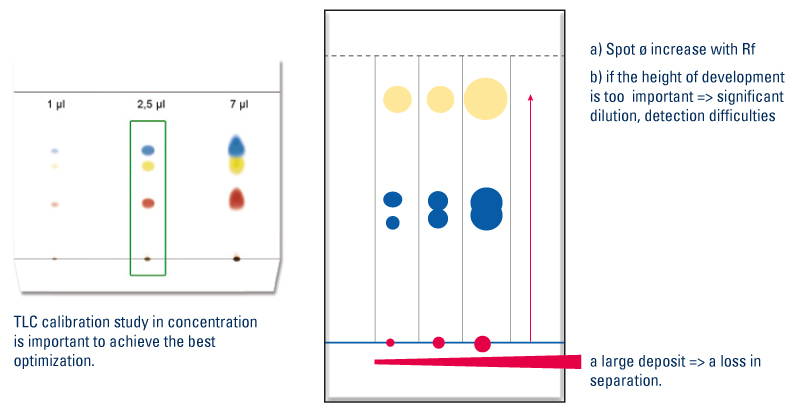

b) Size of the Deposition

The deposition needs to be spread as minimally as possible to avoid losing separation quality. If multiple depositions are needed, ensure the plate dries completely between each one. Let it air dry for about 10 minutes at room temperature before proceeding with further development.

The size of the deposition significantly impacts the separation process. Larger deposits lead to broader spots and reduced resolution.

3. Raw Sample Deposition

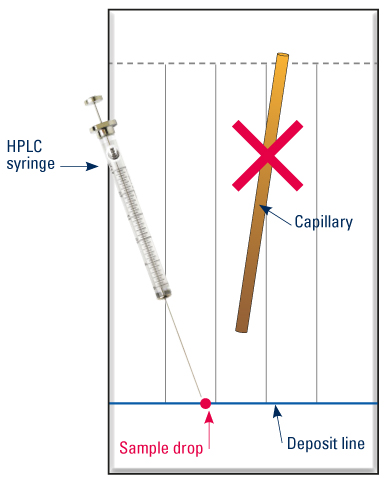

a) Spot Mode

Depositing via capillary action using an HPLC syringe or capillary can cause varying degrees of solute penetration into the adsorbent layer. Smaller deposits yield better results when using a syringe compared to a capillary. This method may distort the spots to some extent.

To minimize distortion:

- Use the smallest possible drop to avoid overloading and subsequent spreading.

- Avoid touching the TLC plate with the deposition tool to reduce deep penetration.

- Note that spot density and distribution can change based on solvent polarity.

- Keep the spot away from the plate’s edges.

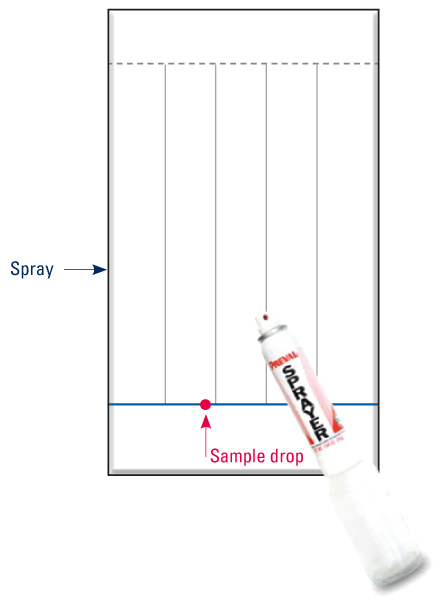

b) Spray Mode

Using a spray bottle, control the spray speed so it's slower than the solvent's evaporation rate to prevent splashing. In this mode, the solute remains mostly on the surface without significant penetration. This leads to less dispersed spots and optimal separation.

Solvent for Dilution

Choose a solvent with minimal elution strength, ensuring it’s highly pure. It should be polar enough to dissolve the sample but not overly so to facilitate easy elimination. Avoid using bases and acids excessively. Steer clear of viscous or high-boiling solvents like N,N-Dimethylformamide, DMSO, BuOH, or water, as these slow down the solvent movement. Always let the plate dry between successive depositions.

Solvent for Elution

Adjust the elution strength according to the compound’s polarity to keep Rf values within the ideal range (0.15 – 0.35). The mobile phase's velocity isn't consistent across the entire plate. Use the same mobile phase for both TLC and flash purification.

Preparing the Mobile Phase for Seamless Transfer to Flash Purification

Measure solvents accurately using calibrated flasks. Low-volume percentages can be measured more precisely with a syringe.

For a better understanding of TLC to Flash chromatography integration, consider downloading our app "TLC to Flash & Prep Chromatography."

Know More:

---

As chromatographers, we're always looking for ways to improve our techniques. Whether you’re working with complex mixtures or fine-tuning your methods, the deposition and elution processes play a critical role. Remember, small adjustments in deposition size, solvent choice, and drying times can significantly impact your results. If you’re new to chromatography or want to optimize your current workflow, feel free to reach out or explore our resources. Happy chromatographing!