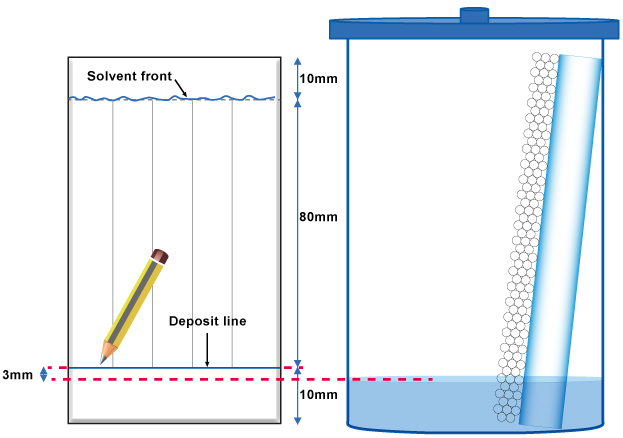

1. Deposit Line & Solvent Front

When plotting the deposit line, use a pencil and place it about 3mm above the mobile phase level. It’s recommended that the migration height be at least 8cm. Ensure that the solvent front moves up to 1cm from the top edge of the TLC plate.

2. How to Make the Deposit

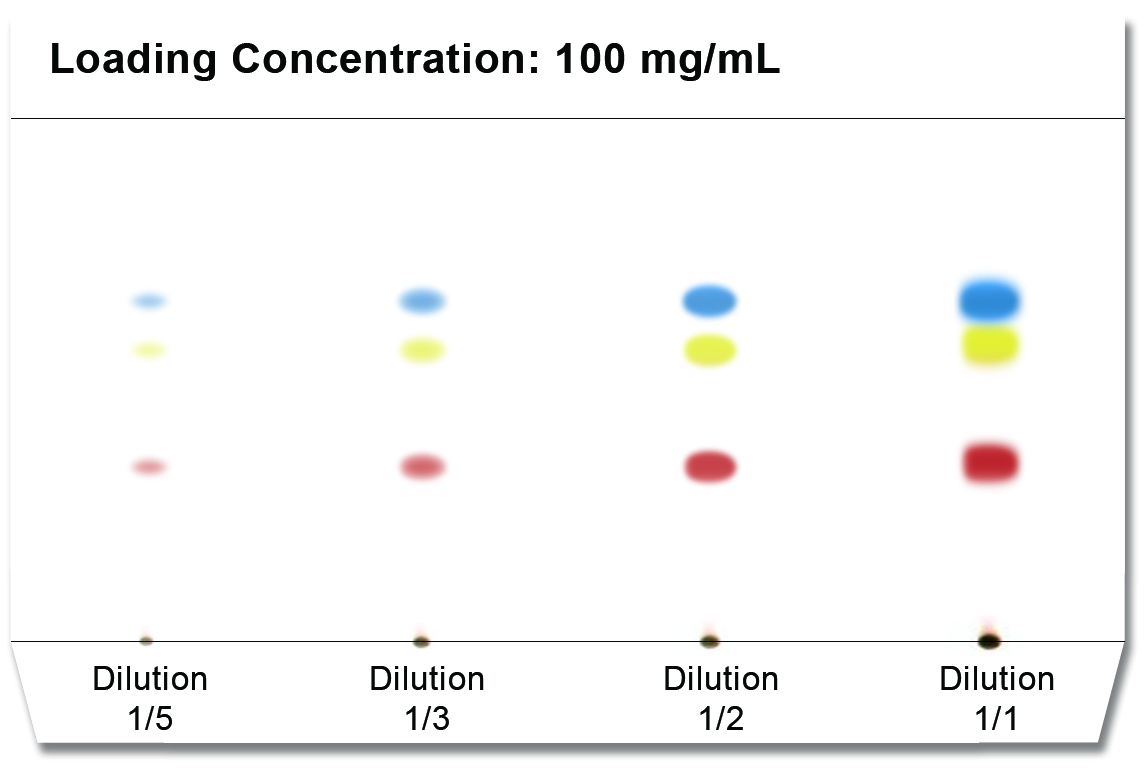

a) Sample Concentration

To avoid overloading, it’s crucial to maintain the right concentration. For a standard, aim for a concentration of 0.1mg/L. For the sample, the concentration should not exceed 2%.

|

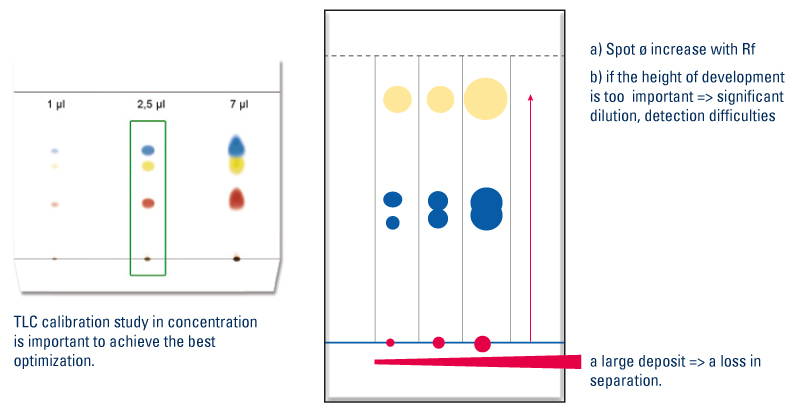

b) Deposit Size

The deposit needs to be spread as minimally as possible to prevent losing separation efficiency. If you plan to make multiple deposits, let the plate dry thoroughly between each one. Afterward, allow the plate to air dry for at least 10 minutes at room temperature before developing it further.

The size of the deposit greatly affects separation quality—smaller deposits yield better resolution. Here's how different deposit sizes impact the separation based on Rf values:

|

3. Raw Sample Deposition

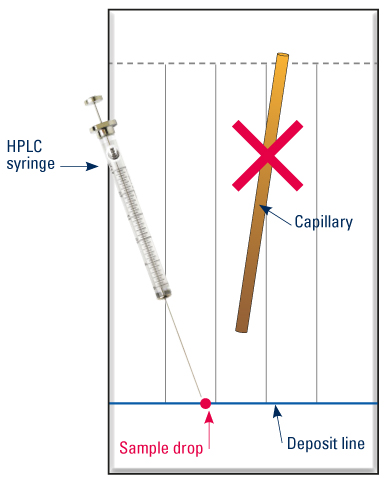

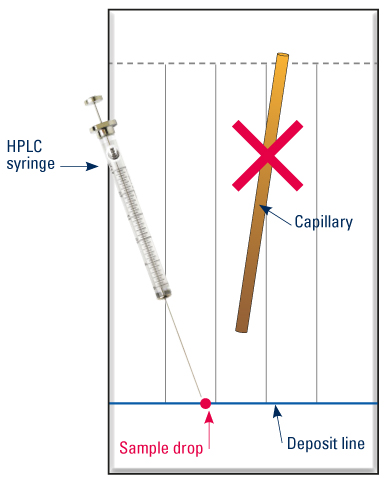

a) Spot Mode

Using capillarity with an HPLC syringe or capillary, the solute penetrates more or less deeply into the adsorbent layer. Fine deposits are best achieved with a syringe rather than a capillary. This method can cause some deformation of the spots. To minimize dispersion due to overloading, load the smallest drop possible. Avoid touching the TLC plate with the deposit tool to reduce deep penetration into the plate. Spot density and dispersion can vary depending on solvent polarity. Keep spots away from the plate edges.

|

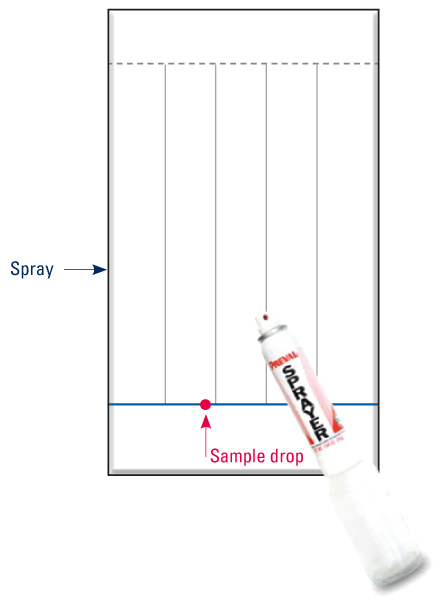

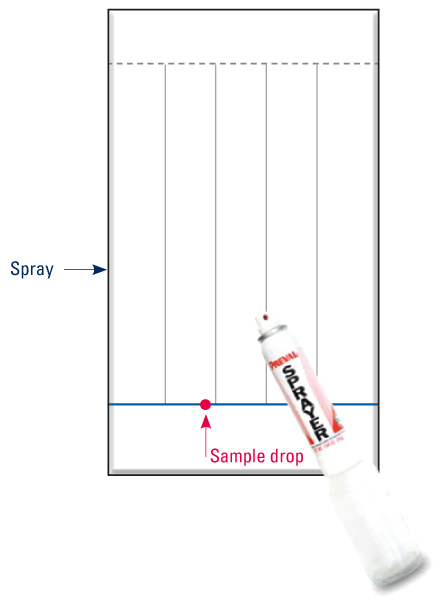

b) Spray Mode

With a spray bottle, ensure the spray speed is slower than the evaporation rate to prevent splashing. This method results in minimal penetration of the solute into the adsorbent layer, keeping it on the surface. Eluted spots are less spread out, leading to optimal separation of migration spots.

|

|

Solvent of Dilution

Choose a solvent with low elution strength, ensuring it’s very pure. It should be polar enough to dissolve the sample but not overly so to hinder easy elimination. Acidic and basic additives should be used sparingly. Avoid viscous and high-boiling solvents like N,N-Dimethylformamide, DMSO, BuOH, and water, as they increase the migration time. Allow the plate to dry completely between successive deposits.

Solvent of Elution

Adjust the elution strength according to the compound's polarity to maintain Rf values within the optimal range (0.15 – 0.35). Mobile phase velocity varies across the plate. Use the same mobile phase for TLC and Flash purification.

Preparing the Mobile Phase

For seamless transfer to Flash purification, measure solvents precisely using separate flasks (check their calibration). Low-volume percentages can be measured with a syringe for added precision.

|

Learn More:

- Contact Us: [Your Contact Information]

- Visit Our Website: www.interchim.com

- Explore Our Purification Systems

- Enhance Your TLC Experience with Our "TLC to Flash & Prep Chromatography" App

---

While performing these procedures, always remember that small adjustments can significantly impact your results. It’s essential to carefully calibrate equipment and follow protocols to ensure reproducibility. Additionally, maintaining clean and well-calibrated tools will help achieve consistent outcomes. If you encounter challenges, consider reaching out to our support team for assistance.

Anchovy Fish

Anchovy Fish

Anchovy Fish,Frozen Anchovies,Raw Anchovies,Flat Anchovies

ZHEJIANG EVERNEW SEAFOOD CO.,LTD , https://www.evernewseafood.com